Water purification methods that are outdated can no longer be relied upon in an age of precision manufacturing and strict water quality standards. Ensure product safety, process consistency, and compliance with environmental regulations with a modern solution like the Ultrafiltration System.

A membrane-based filtration process, ultrafiltration (UF) System, removes suspended solids, bacteria, viruses, and high molecular weight organics from water. The combination of its efficiency, eco-friendliness, and reliability makes it the perfect choice for a variety of industries.

Why Industries Depend on Ultrafiltration

- Consistent Water Purity:

Ultrafiltration membranes filter particles as small as 0.01 microns, ensuring microbial and physical contaminant removal, critical for industries like pharma, food, and electronics. - Protects Equipment and Processes:

Ultrafiltration System serves as a key pre-treatment step for Reverse Osmosis (RO) and other downstream systems. Without UF systems face rapid fouling, higher maintenance, and costly downtime. - Stable Output in Unstable Water Conditions:

Source water often varies in quality. UF System ensures consistent output even when input water fluctuates in turbidity or contamination—ensuring uninterrupted operations. - Reduces Chemical Dependency:

Unlike conventional clarification, the Ultrafiltration (UF) System operates without chemicals, making it safer, more sustainable, and cost-effective over time. - Compact & Scalable:

UF systems are modular and space-saving, easy to install and expand, adapting to changing industrial needs.

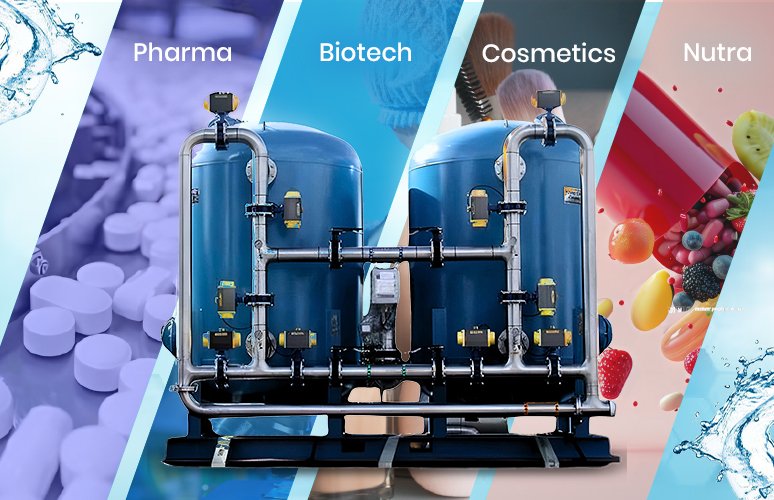

The Ultrafiltration (UF) System has become essential for industrial water treatment today, especially in critical sectors like Pharmaceuticals, Biotechnology, Cosmetics, and Nutraceuticals, where water purity directly impacts product safety and compliance. In the pharmaceutical and biotech industries, UF ensures the removal of bacteria, endotoxins, and high-molecular-weight contaminants, supporting stringent GMP and USP standards. Cosmetic manufacturers rely on UF-treated water to maintain product stability and avoid microbial contamination that could compromise skin safety. Similarly, in the nutraceutical industry, ultrafiltration guarantees high-quality water for blending, cleaning, and processing, ensuring consistency and regulatory compliance. Across these sectors, UF systems serve as a reliable barrier for pre-treatment and final polishing, enhancing product integrity and operational efficiency.

What Happens If an Ultrafiltration System Is Not Used?

- Contaminants enter critical processes, leading to product failure or batch contamination.

- RO membranes clog quickly, increasing downtime and repair costs.

- Regulatory violations may occur due to non-compliant water quality.

- Long-term equipment degradation reduces system efficiency.

Conclusion

Ultrafiltration is no longer optional—it’s a core component of modern water treatment. Collaborating with a trusted Ultrafiltration Plant manufacturer in India ensures high performance, regulatory compliance, and long-term savings.

Comments are closed